WJ is a long-established industry leader and innovator in dewatering and hydrogeology management systems in the UK. A complex and high risk project took us to the heart of Suffolk to offer our expertise to the constructors of a new Tidal Barrier Gate at Ipswich’s River Orwell.

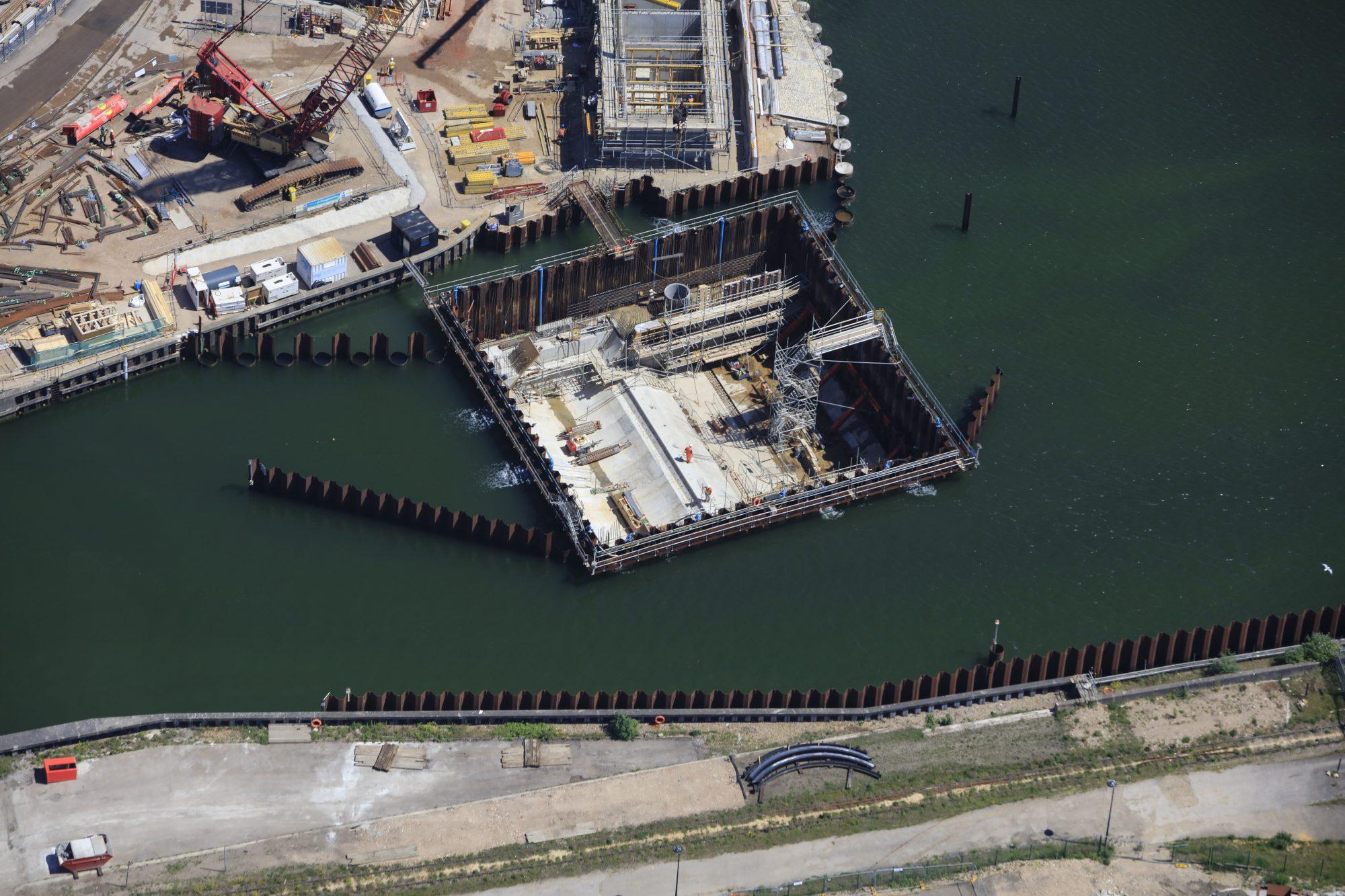

Ipswich is located at the mouth of the River Orwell, and it has long been affected by flooding from both high river flows and tidal surges. The Environment Agency determined that the best way to prevent these surges, control flow, and to minimise the impact of any flooding, was to construct a 20-metre-wide tidal barrier gate across the river mouth.

WJ designed the dewatering system, for the Ipswich Tidal Barrier, so the contractor could build the cofferdam with a series of preformed steel tubes inside and outside of the structure to allow for the installation of dewatering wells and monitoring points to depths of 20 and 14 metres. The contractor installed the steel tubes by percussive methods into the sand and gravel below the riverbed. The installation process was particularly challenging due to access constraints, and it was necessary to undertake a trial well installation using an innovative ‘lost bit’ technique, which prevents the steel tube from filling up with material, prior to the main installation works. WJ then installed a pvc well liner and filter gravel backfill allowing the steel tube to be removed by vibration, leaving a screened well in place.

WJ’s deep well system was pumped successfully over a period of 10 months, in line with the client’s programme. Discharge flow rates between 65 litres per second (l/s) and 90 l/s were recorded, with all the discharge being deposited straight back into the River Orwell. Once the works had progressed and the discharge flow rates reduced, it became necessary to downgrade the pumps on-site. This posed a logistical challenge as the excavation had already progressed significantly below the installation level of the wells, and they had to be accessed from the handrail level of the cofferdam. Working with the client, WJ Groundwater’s skilled and experienced operatives used a unique pump riser system and were able to minimise the amount of time the crane was utilised for the pump exchange.

In order to extract the decommissioned pumps and other equipment once our contribution to the task was complete, a phased removal of one month was scheduled. WJ’s famous flexibility and ability to respond at short notice ensured that no other aspects of the construction of the barrier were affected.

WJ Groundwater has completed similar groundwater management projects in the UK and globally. Click on the links below to learn more about what we do.

Are you ready to see what else our vision can bring to your projects? Why not speak to our team of groundwater experts today?