Since our formation in 1981 WJ have an outstanding record working on some of the largest and most complex infrastructure projects in the UK, and in particular, in and around London. When it was announced that a new tunnel the River Thames was to be constructed, which would link Kent and Essex and help alleviate pressure on the Dartford Crossing, it was a project that at WJ we were keen to provide our experience and expertise on.

Understandably a project of this scale would require extensive investigations to understand the geological and hydrogeological properties of the crossing and the two portal sites. It was for the North Portal site where WJ were engaged by a Joint Venture between SOCOTEC and Perfect Circle JV, with the aim of undertaking pumping tests to inform the design of an appropriate groundwater management strategy for the construction phase.

As well as drilling and installing the pumping test and monitoring wells, and undertaking the pumping test itself, WJ were also responsible for the implementation of an extensive monitoring regime comprising:

- Inline and in-situ multiparameter water quality measurements.

- Flow Monitoring

- Real -time water level, temperature and electrical conductivity monitoring.

- Water sampling and quality testing.

- On-site ammonium testing.

- Daily visual inspections.

As you can imagine this required a significant commitment of resources, all set against the backdrop of COVID-19 restrictions. Due to the critical nature of the tests and each testing phase, WJ deployed multiple monitoring teams to ensure sonde installations, in-situ water quality readings, water samples and water level readings were obtained correctly and as required.

Due to the nature of the site, mobilisation of groundwater contaminants during test pumping were highlighted as a potential area of concern by the design team. WJ were therefore provided with action levels based on the analytical results of the groundwater and surface water baseline sampling, which was applied throughout the pumping stage. WJ implemented a two-tier system with an “Early Warning” followed by a “Critical Level Warning” with clear action plans associated with breaches of each tier.

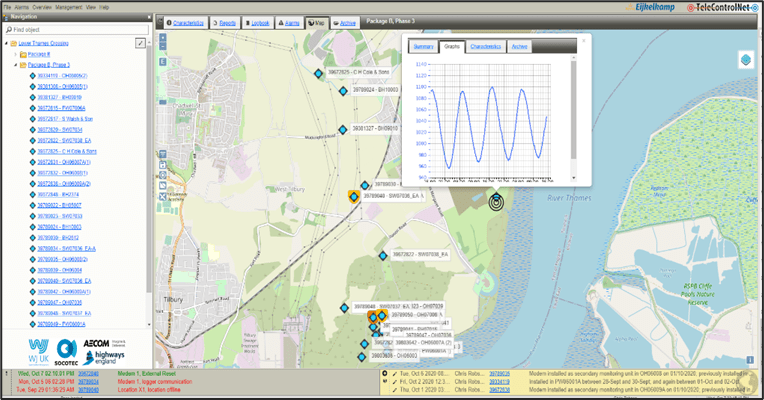

Continuous monitoring of the physical parameters through the test (pH, EC, Turbidity, Dissolved Oxygen, Salinity, ORP and Temperature) via an inline water quality sonde situated in our bespoke pumping test cabin with readings undertaken at 10 minute intervals and automatically transferred to our operatives for review and analysis. In addition sondes were installed throughout the project in over 36 observation boreholes and stilling wells, providing real-time monitoring of water levels, electrical conductivity and temperature, which was provided to our operatives and the client via our bespoke online monitoring dashboards, alongside the pumping test data.

Due to the careful and combined diligent management of the Project Manager, Project Engineer, Monitoring Supervisor and all of the operatives involved we ensured a successful project delivery.

- LOCATION: Essex

- CLIENT: SOCOTEC / Perfect Circle

Related Projects

Birmingham Women’s & Children’s Hospital

HS2 Bromford Tunnel