Sub-Surface Dewatering for an Inclined SCL Tunnel

WJ Whitepaper

Abstract

The Crossrail station at Liverpool Street, London required the downward construction of a 37 m long by 6 m diameter inclined ventilation tunnel using sprayed concrete lining (SCL) techniques. The tunnel penetrated into water bearing channel sands present in the Lambeth Group below the London Clay.

This paper describes the development and implementation of an inclined sub-surface ejector well scheme which was used to target and depressurise the channel sands. Access constraints meant that some of the wells were installed from the face part way along the tunnel. The face was enlarged locally to facilitate well installation.

AUTHORS:

T.O.L. Roberts (WJ), A. Stårk (BeMo) and W. Zeiszig (BeMo)

- WJ Groundwater Ltd, London, UK

- BeMo Tunnelling, Innsbruck, Austria

DATE:

2015

SUMMARY:

This paper describes the development and implementation of an inclined sub-surface ejector well scheme which was used to target and depressurise the channel sands. Access constraints meant that some of the wells were installed from the face part way along the tunnel.

1. Introduction

Crossrail is a major new east-west rail link through central London. The main running tunnels have been driven by tunnel boring machine (TBM) with most of the stations and link tunnels constructed using sprayed concrete lining (SCL) techniques.

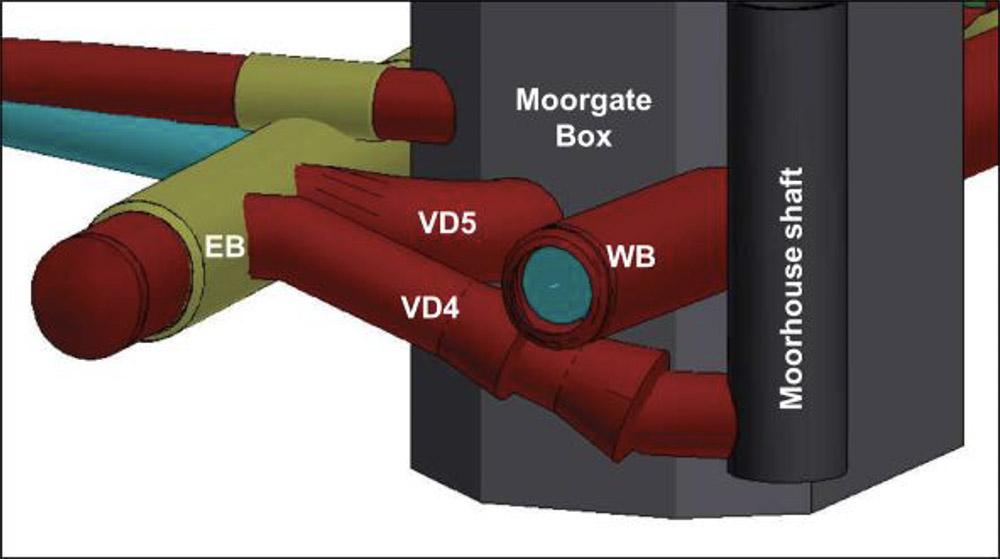

This paper is concerned with the dewatering and depressurisation measures required for Ventilation Duct 4 (VD4) which comprises a 37m long by 6m diameter inclined ventilation tunnel for the Crossrail Liverpool St Station at Moorgate in London. As shown in Figure 1 and 2, VD4 links from the Eastbound Launching Chamber (EB) down below the Westbound Launching Chamber (WB) to an existing shaft. The TBM running tunnels were not constructed at the time of the VD4 works.

The existing shaft was constructed for Crossrail in 2004/5 (several years prior to the main Crossrail works) in the basement of an office development known as Moorhouse. In order to avoid the need to handle potentially large volumes of slurry, the shaft was constructed in ‘dry’ conditions by underpinning. The construction of the shaft has been described in some detail in previous publications (Morrison et al 2004; McNamara et al 2008).

The method of shaft construction required depressurisation measures to be adopted to allow excavation through several water bearing horizons including non-cohesive sands (Lambeth Group Laminated Beds and Lower Shelly Beds) present at the level of the connection to VD4.

The depressurisation measures required for the shaft construction were successfully achieved using ejector wells installed from surface around the shaft. The wells were operated from the second basement level. The shaft is 8.2m diameter and sufficiently deep (38m below basement level and 50mbgl) that depressurisation wells were also needed to target the Lower Aquifer (Lambeth Group Upnor Formation and Thanet Sand). Investigations at the start of the VD4 works confirmed that the shaft dewatering wells had been grouted up sometime after the shaft works had been completed.

The purpose of the depressurisation works for VD4 was to reduce pore pressures at the tunnel horizon to zero or below to allow the tunnel to be constructed using SCL techniques.

1.1. Ground Conditions

Information on ground conditions in the vicinity of VD4 was available from a number of sources which included:

- Historic boreholes dating from the Moorhouse development.

- More recent boreholes installed as part of the investigations for Crossrail.

- Published records from the construction of the existing Moorhouse shaft.

- Logs of probe holes, piezometer installations and well installations undertaken as part of the Crossrail Liverpool St Station works.

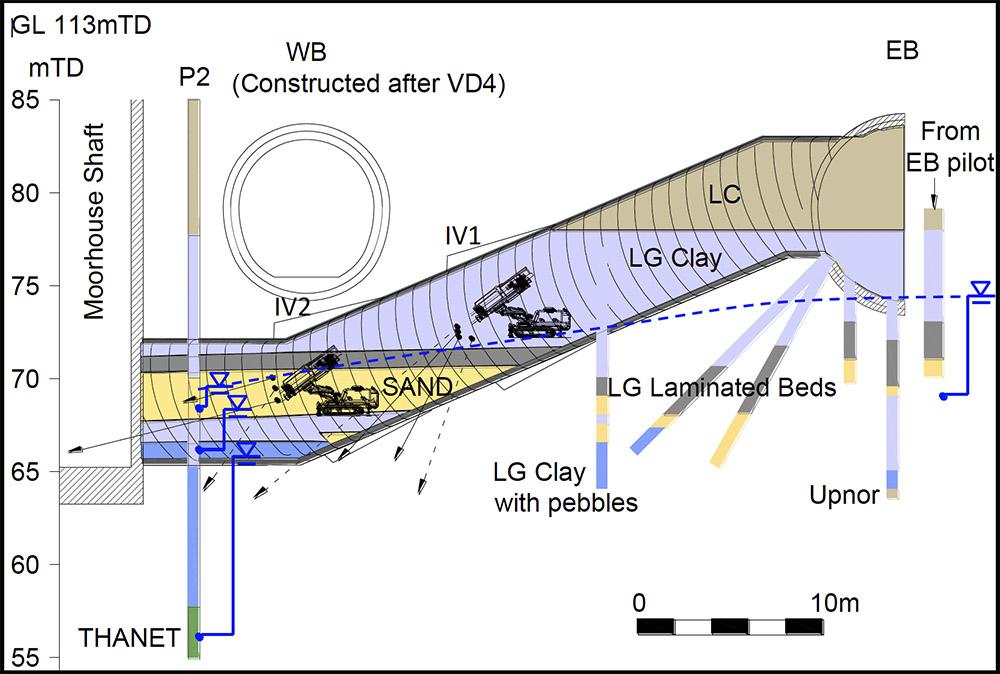

This information is summarised on the section in Figure 3. This shows that the London Clay (LC) / Lambeth Group (LG) interface is at approximately axis level in the EB tunnel. The top of the Thanet Sand is approximately 7 m below invert level for the deepest section of VD4 adjacent to the Moorhouse shaft. It can be seen that the invert for VD4 is entirely in the Lambeth Group with the crown commencing in the London Clay before entering the Lambeth Group.

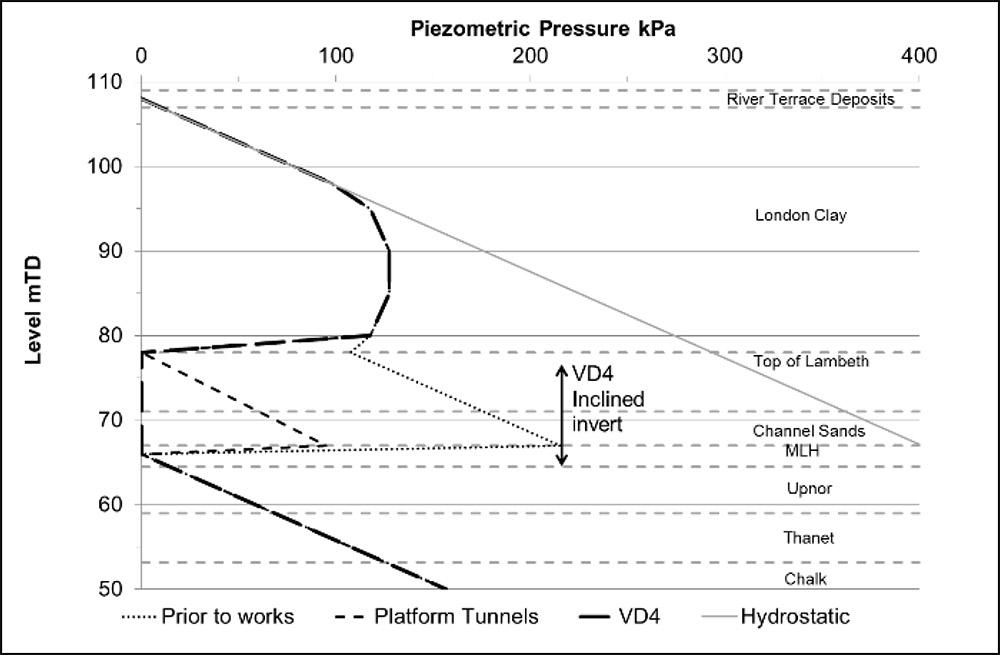

Figure 3 shows the presence of a sand horizon which runs through the inclined invert and axis of VD4. A second water bearing horizon is present in the lower Lambeth Group at the lowest invert level adjacent to the shaft. The pore pressure profile prior to the start of the works on the new station is given in Figure 4. This is based on monitoring information from approximately twenty piezometers monitored intermittently between 1992 and 2010. This is typical of the prevailing under drained pore water pressure profile present in central London.

Over abstraction from the chalk between about 1850 and 1965 has reduced ground water levels in the Lower Aquifer below London comprising the Lambeth Group Upnor Formation, Thanet Sand and Chalk. Groundwater levels started to rise between 1965 and 1990 but are now maintained by pumping from wells across London to protect the extensive deep infrastructure which was constructed after groundwater levels had been lowered (Environment Agency 2014). Groundwater levels in the Terrace Gravels (Upper Aquifer) above the London Clay are largely unchanged. The London Clay and Lambeth Group clays form a dividing layer between the Upper and Lower Aquifers. Figure 4 shows that the non-cohesive granular horizons which are intermittently present, mainly in the upper Lambeth Group, have not fully drained and form an Intermediate Aquifer. The Crossrail site investigation works have shown that the Mid-Lambeth Hiatus (MLH) is the approximate boundary with non-cohesive horizons below this level generally reflecting groundwater levels in the Lower Aquifer whilst those above are found to generally exhibit elevated pore pressure between those in the Upper and Lower Aquifer.

The precise explanation as to why elevated pore pressures persist in the Upper Lambeth Group is not immediately clear. It is a common misconception that the elevated pore pressures in the Lambeth Group are relic and once dissipated will not recover. This is almost certainly partly true in so far as the highest pressures, those above 100 to 150kPa, have proved elusive to reproducible measurement. Pressures that are below this do tend to recover, at least partially, when pumping stops.

Whilst the vertical permeability of the lower Lambeth Group clays is clearly very low (probably <10-9 m/s) it seems unlikely that elevated relic pore pressures could be sustained over more than 100 years without some form of seepage inflow which exceeds the downward leakage outflow. The possible sources of seepage inflow to the Upper Lambeth Group sands include:

- Leakage from the London Clay. The LondonClay has a similarly low permeability to theLambeth Group clays and is significantlythicker. The reduced pore pressure noted in theLondon Clay on Figure 4 suggests this mayprovide some contribution.

- Leakage via natural fissures or scour featuresin the London Clay. Seepage flows areoccasionally evident in sand laminations orLimestone bands towards the base of theLondon Clay. Scour features which penetrate through the London Clay do exist but are relatively rare.

- Seepage from the upper aquifer via un-grouted or poorly grouted boreholes. There are many site investigation boreholes and redundant wells across London but little factual evidence that these provide a significant flow path through the London Clay.

- Horizontal seepage from areas where the Lower Aquifer groundwater levels are above the Mid-Lambeth Hiatus. This could be a factor but the distances involved are several kilometres.

All of the above may have a part to play but their relative significance remains unclear.

1.2. Experience from Station Tunnels

Access from ground level to the VD4 works was via a temporary shaft in Finsbury Circus and the largely complete station tunnels and pedestrian tunnels. For the most part excavation and SCL primary lining of these had been completed with secondary lining works about to commence. The crown of the station tunnels is in London Clay and Lambeth Group soils, with the potential for water bearing sand horizons, are present from approximately axis level.

The station tunnels were constructed in a sequence comprising an SCL pilot tunnel driven for the full length followed by an enlargement with top heading, bench and invert. An assessment of the SCL works based on the highest credible pore pressures recorded indicated that the required clay cover below invert was approximately 3m for the pilot tunnel and 4m for the enlargement. A careful review of the lithology of the Lambeth Group confirmed that sand horizons were generally sufficiently deep that the vast majority of the pilot tunnel works could be constructed without the need for active depressurisation.

The depressurisation strategy that was adopted for the station tunnels was regular overlapping forward inclined auger probe drilling in the advancing face of the pilot tunnel. Vertical probe drilling was then undertaken from the completed pilot tunnel to confirm conditions for the enlargement. Where water bearing channel sands were encountered, the probe holes were then completed as wellpoints and connected to a vacuum dewatering pump. The effectiveness of these measures was monitored by using un-pumped wellpoints as standpipes. It proved impossible to preserve wellpoints installed in the pilot tunnel through the enlargement sequence. This strategy was found to be generally satisfactory other than the occasional need to re-install wellpoints lost in the course of the enlargement works. This was particularly the case where sand horizons were present above the invert of the enlargement. The proximity of the station tunnels sometimes allowed wellpoints to be installed from a completed tunnel to depressurise an adjacent tunnel under construction. Also, where it was necessary to operate a wellpoint system in a blind pilot tunnel, it was sometimes feasible to install a connection bore for power and discharge which avoided passing these services through the advancing enlargement face.

1.3. Access Constraints

VD4 is located in the heart of one of the busiest cities in the world and it was immediately apparent that constraints on access would be the primary driver for the depressurisation strategy. Access to the shaft at Moorhouse was now in the basement of an occupied office building. In due course improved access from the surface to the basement would become available to allow secondary lining and fit out of the shaft but this was for a separate contract later in the program.

In any case headroom in the completed basement was insufficient to reinstate the surface wells around the shaft. The remainder of VD4 was below existing occupied buildings or below the congested construction site for the adjacent Moorgate Box ticket hall. Access from the Moorgate Box was not available as it was under construction.

Access from the WB SCL launch chamber immediately above VD4 was not available as it had not yet been built. The remaining available options for installation of the depressurisation wells were from the EB tunnel, from the adjacent VD5 tunnel and from the face of VD4.

2. Depressurisation Strategy

The central 28m section of VD4 slopes down at an angle of 23o from the horizontal. This is too steep for conventional excavation plant to work safely and the lack of useable access to Moorhouse shaft meant a down slope excavation sequence, using an excavator adapted for the purpose, was required. The in-tunnel wellpoint strategy for the station tunnels had been successful; however it was apparent that the access constraints, geometry and alignment of VD4 plus the expected geology required a modified approach.

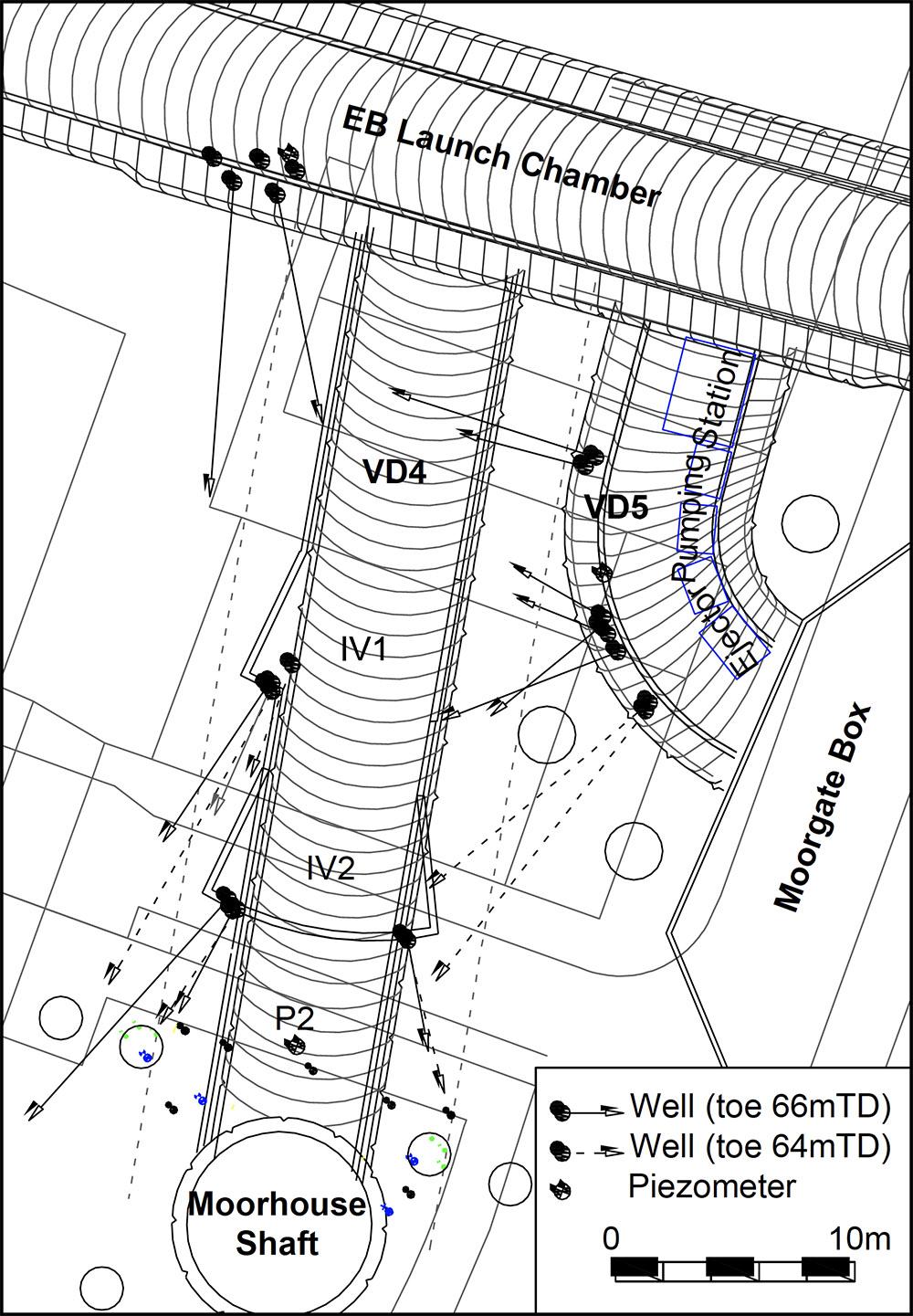

Depressurisation of the first part of VD4 could be achieved using wells installed from the adjacent VD5 tunnel and the end of the EB tunnel. Installation level for these wells was approximately 76mTD; over 10m above the lowest invert level for VD4. The required suction was then too great for wellpoints, requiring resort to an ejector scheme. The ejector pumps and recirculating tanks could usefully be accommodated in VD5 without hindering access to VD4 (Figure 5).

One of the piezometers (P2 on Figure 5) installed for the Moorhouse shaft works remained accessible and was recommissioned. The installation comprised a standpipe with a response zone at 63.5 to 64.5mTD (at VD4 invert) plus two vibrating wire transducers with response zones at 68 to 69mTD (Lambeth Group sand channel) and at 56.5mTD (Thanet Sand).

Monitoring data from these instruments confirmed the pore pressure profile shown in Figure 4. A 24 hour pumping test was conducted on the wellpoints installed for the EB Tunnel works at the entrance to VD4. This resulted in a response of just 0.2m in the sand channel at P2 indicating some hydraulic connection but also confirming that pumping in this area would be unlikely to achieve the drawdown required as VD4 approached the shaft.

In order to address this two intervention locations (IV1 and IV2, see Figures 3 and 5) were identified for in-tunnel ejector well installation. The face was enlarged at each intervention so that the wells could be drilled inclined down and forward but would not then need to be broken out for subsequent advances. Pipework was run down the side of VD4 connecting the ejector wells back to the pumping station in VD5. The final well array installed is shown in Figure 5. The planned well array comprised 30 ejector wells; 26 targeting the sand channel on each side of VD4 at 3 m spacing with 4 targeting the lower water bearing horizon present at invert. This was reduced to 15 No. ejector wells plus 6 targeting the lower horizon based on feedback from the monitoring and face logs from the tunnelling. The SCL enlargement at the second intervention and the drill rig set up in VD4 are shown in Figure 6.

3. Monitoring Results

Monitoring data from the piezometers installed in VD5 and from P2 is given in Figure 7. Also shown is the discharge flow rate from the ejector system. The upper piezometer in VD5 recorded a significantly higher pore pressure throughout. This piezometer did respond to pumping; see for example the two up spikes in late August when the pumping was briefly interrupted due to power outages.

No significant seepage flows were encountered during excavation of VD4 suggesting that the high-level sand horizons in the vicinity of VD5 and the EB tunnel was not directly connected to the main sand channel in the vicinity of the Moorhouse shaft.

Piezometer P2, 69mTD, indicated that a vacuum had developed in the sand channel when pumping commenced. This increased when additional ejector wells were installed at the first intervention at the end of July. The additional wells installed at the second intervention did not further improve the drawdown. The piezometers in the lower water bearing horizons were just above invert level which led to a decision to increase the number of wells which targeted this horizon.

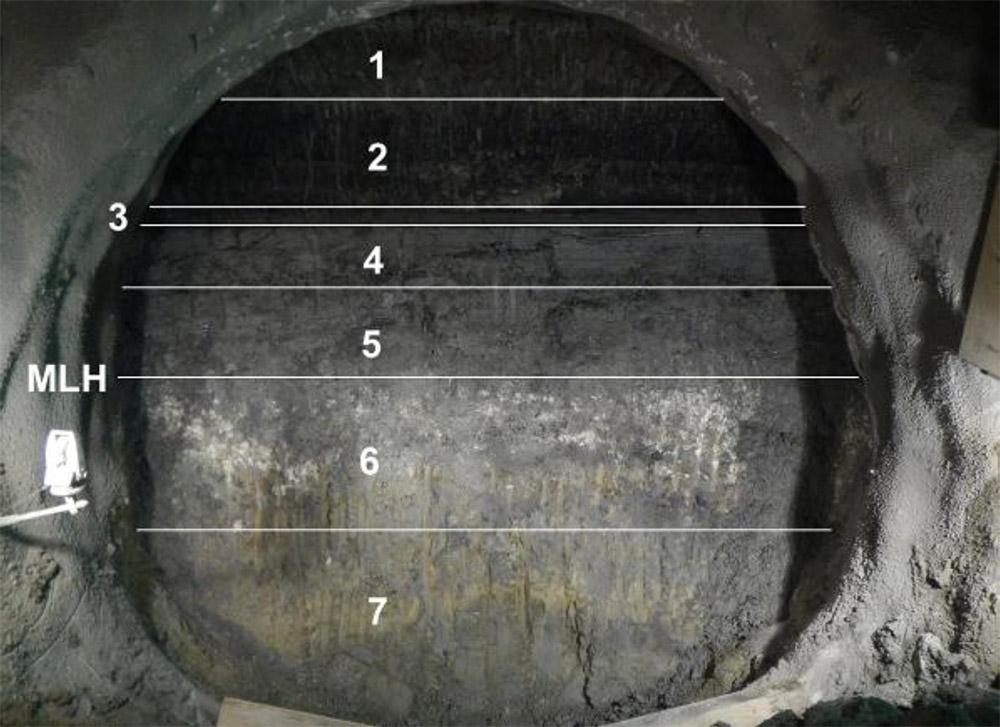

The face exposures during the SCL advances gave an excellent opportunity to assess ground conditions and log the face. The information collected was used to continuously refresh and update the ground model. An example of the logging of the face exposure is given in Figure 8 and Table 1.

Table 8: Photograph of VD4 face 4m from Moorhouse shaft.

4. Conclusions

The complex stratification and intermittent nature of non-cohesive horizons makes depressurisation of the Lambeth Group often less than straightforward. This was further complicated at VD4 by restricted access and awkward geometry which led to the decision to deploy an inclined in-tunnel ejector well dewatering system.

This allowed maximum use of the limited access available and also allowed the option of close well spacing along both sides of the alignment with just two interventions.

Acknowledgements & References

Acknowledgements

Many individuals contributed to the success of this project and the authors would like to acknowledge the project client Crossrail, the permanent works designer for the SCL tunnels Mott Macdonald, the main contractor BBMV (Balfour Beatty, BeMo Tunnelling, Morgan Sindall, Vinci) the temporary works SCL designer Morgan Sindall Underground Professional Services and the dewatering subcontractor WJ Groundwater Ltd.

References

Environment Agency. 2014. Management of the London Basin Chalk Aquifer: Status Report, Environment Agency, London.

McNamara, A.M. Roberts, T.O.L. Morrison P.R.J. & Holmes, G. 2008. Construction of a deep shaft for Crossrail, Proceedings of the Institution of Civil Engineers, Geotechnical Engineering 161, 299–309.

Morrison P.R.J. McNamara, A.M. & Roberts, T.O.L. 2004. Design and construction of a deep shaft for Crossrail, Proceedings of the Institution of Civil Engineers, Geotechnical Engineering 157, 173–182.

Link

To read the full, original published paper, please click on the link below: