At WJ we are all part of one large family and sometimes it’s important for our staff to have a bit of downtime. On the 13th September a number of our staff took to the golf course to take part in the annual British Drilling Association Golf Day.

read moreUK

Carl Gawtry 1956 – 2024

Dan Carpenter June 6, 2024All at WJ are shocked and saddened to learn of the untimely passing of Carl Gawtry on 4th June 2024.

read moreWJ Featured in Construction Industry News

Dan Carpenter July 3, 2023In April 2023 WJ were pleased to learn that we have been shortlisted (for the second successive year!) for the Ground Engineering 2023 Awards Contractor of the Year.

read moreGround Engineering Awards 2023

Dan Carpenter April 3, 2023WJ are pleased to announce that we have been shortlisted (for the second successive year!) at the Ground Engineering 2023 Awards, in the prestigious category of Contractor of the Year!

read moreWJ Ski Trip 2023

Dan Carpenter February 14, 2023At WJ we work hard, but we also play hard, and after the success of our first staff holiday in 2022, twelve of our WJ UK staff, and two of our of staff from WJ ME returned to the slopes for a well-earned break!

read moreSebastian Fisher 1972 – 2022

Dan Carpenter December 12, 2022Everyone is deeply saddened to learn of the recent passing of former employee Sebastian Fisher, at a tragically young age.

Sebastian worked for WJ between 2000 and 2011, and was influential in our growth in the UK and internationally during this time, becoming recognised as one of the leading dewatering exponents in the UK.

We have many fond memories of Seb and send our condolences to Celeste and his family and friends.

Regent’s Park 10km Charity Run

Dan Carpenter November 28, 2022WJ have had a global dewatering presence for more than 20 years with existing offices in the UK, Canada, London’s Regent’s Park is one of the capital cities 8 Royal Parks and is home to London Zoo, floral gardens, tranquil lakes and iconic statues and monuments. It is also home to London’s most popular 10k run.

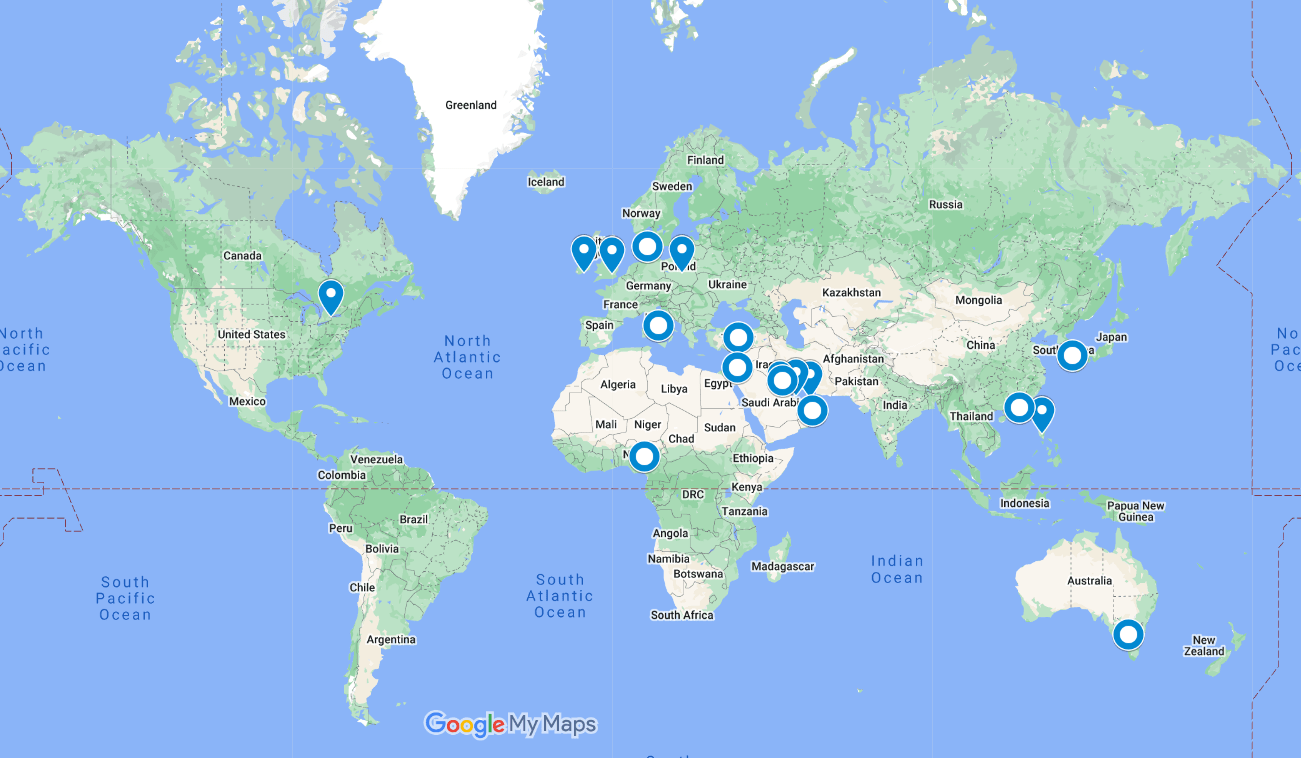

WJ Group continues global expansion with new contract awards in the Philippines

Dan Carpenter November 21, 2022WJ have had a global dewatering presence for more than 20 years with existing offices in the UK, Canada, Poland, UAE, Saudi Arabia and Qatar, and a history of working in many more nations. In April 2021, we were pleased to add the Philippines to this list after being awarded the USD $6m contract for the dewatering of the new Clark-Malolos Railway Station at Clark International Airport, approximately 100km north of the capital city of Manila.

WJ win BDA 2022 Industry Excellence Award

Dan Carpenter November 17, 2022Building a more sustainable and environmentally friendly future for everyone is a major part of WJ’s ethos, and therefore this week everyone at WJ is celebrating WJ’s Commachio plug-in electric drilling rig winning the the Industry Excellence Award at the British Drilling Association’s Annual Awards on Saturday 12 November, at the Gateshead Hilton.

Much of sub-Saharan Africa is considered to be in “economic water scarcity”, where water infrastructure is either poor or mismanaged despite sufficient water sources being present. One way to help manage this issue and provide long term water security to nations is through the construction of high-quality water wells and boreholes. In response to this, WJ, alongside Cranfield University, the British Drilling Association, and RedR UK, as well as a number of other industry partners, combined to provide the “Developing Groundwater” course during October 2022.